Portapipe® can be used in two ways to best meet your requirements:

For horizontal pipes: Portapipe® uses a time-of-flight method to accurately determine the liquid level and display it as a percentage of the tube's capacity.

For vertical piping: Portapipe® uses an on/off method in which the sensor is moved up and down sequentially to detect the liquid level.

An operator can switch between these two methods with the click of a button, meaning Portapipe® can be quickly applied along the entire length of a piping system, regardless of its orientation. This allows Portapipe® to be used for a variety of applications, including pipe fullness measurement, overflow monitoring, clog detection and pipe capacity assessment.

Portapipe® does it all

Portapipe®'s computerized database contains the most commonly used industrial fluids (fuels, flammables, water, etc.) and pipe materials (copper, PVC, carbon steel, etc.) making start-up and measurement easy. New data can easily be entered into this database by an operator with a different fluid or pipe material sound velocity; making Portapipe® a truly versatile device that can be customized to meet your needs.

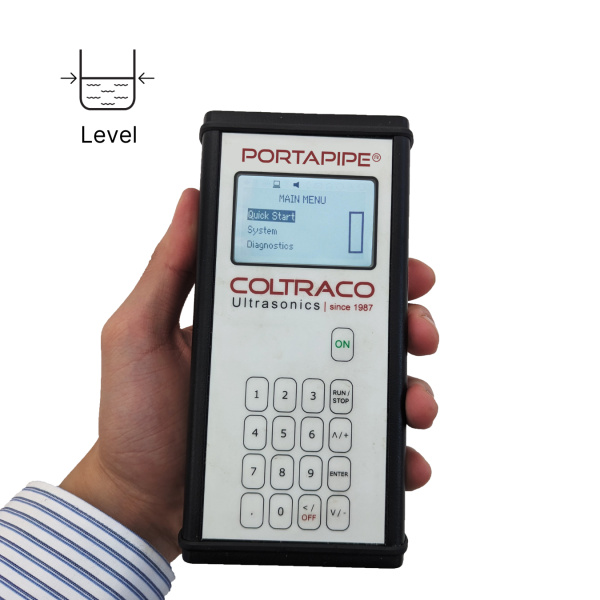

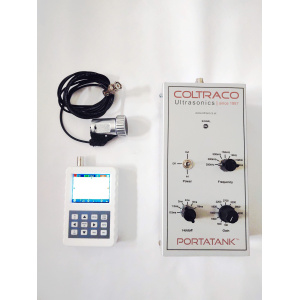

Portapipe® is handy and portable, making it a solution that can be applied to a variety of pipelines in a facility. With its quick and easy measurement process, it can be used to monitor output or detect leaks where and when needed. With two included sensor options, Portapipe® can be customized to indicate levels within different pipe sizes, and its IP 65 rating allows it to be used in even the most challenging contexts.