Mechanical level switches

Mechanical Level Switches

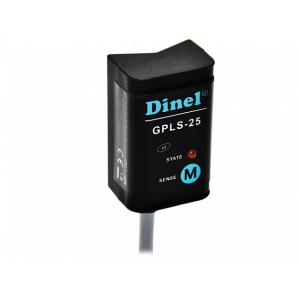

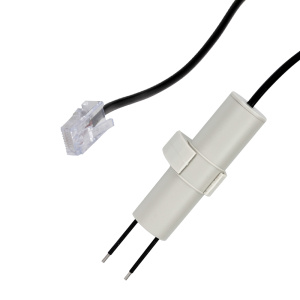

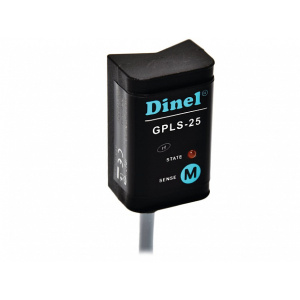

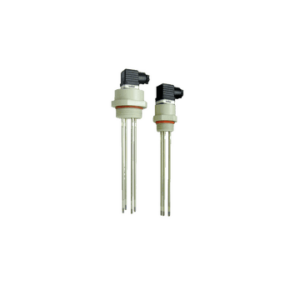

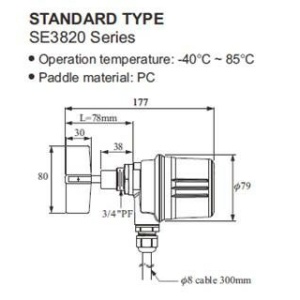

Contactless level detection GPLS-25N-0-A-S-K2 (pipe/tube mounting)

Mechanical Level Switches

Contactless level detection GPLS-25N-1-A-S-K2 (flat mounting)

Mechanical Level Switches

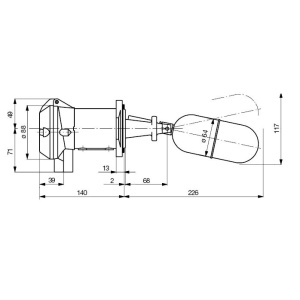

Level switch with larger magnet for 32 mm pipe (clamping band) HMW-3-32-GR

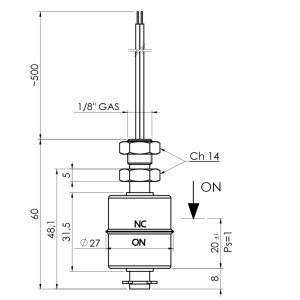

Elettrotec

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

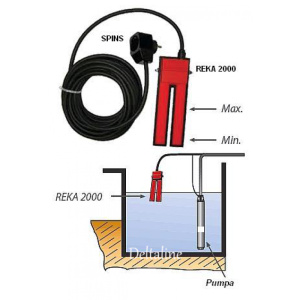

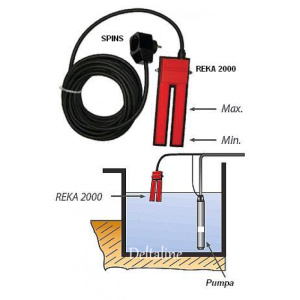

Level switch, REKA 2000 ML-10 mtr, for 230 V pumps (empty pumps)

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Contactless level detection GPLS-25N-0-A-S-K2 (pipe/tube mounting)

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

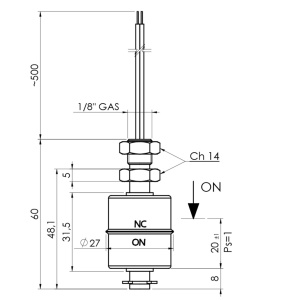

EX LEVEL SWITCH FOR 32MM PIPE / IRN/HMW/32/EX-1G II 2 G EX IA IIC T6

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Level switch, REKA 2000 ML-10 mtr, for 230 V pumps (empty pumps)

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

H-Tronic

Mechanical Level Switches

Mechanical Level Switches

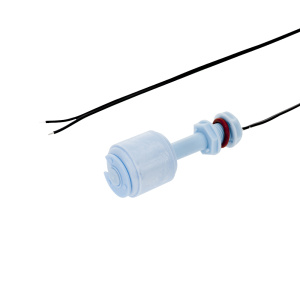

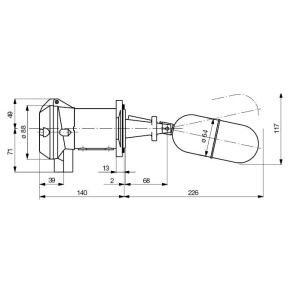

Level switch Type VH602M - 1500 mm cable- stainless steel float

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Compact level transmitter MKLS - MN33-350-550-0-XX (stainless steel float)

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

Mechanical Level Switches

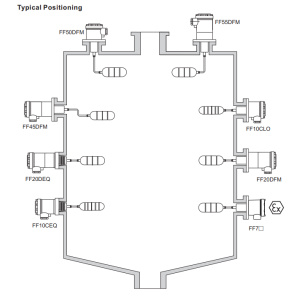

Stainless steel level switch type MULTIPOINT-S / 1-6 control points

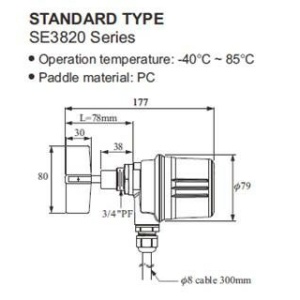

FineTek

Mechanical level switches

Here are some features and applications of mechanical level switches:Simple design: Mechanical level switches generally have a simple design with moving parts, such as float mechanisms or balls, that respond to the level of the fluid.

Robustness: Due to the absence of electronic components, mechanical level switches are often more robust and able to withstand harsh conditions, such as corrosive or explosive environments.

Reliability: They are known for their reliability in various applications because they are less prone to failures caused by such things as dust, dirt or electrical interference.

Easy installation: Mechanical level switches are generally easy to install and maintain, making them suitable for various industrial and domestic applications.

Applications:

Water tanks: Mechanical level switches are often used in water tanks to control water flow or prevent overflow.

Oil and fuel tanks: They are deployed in tanks for oil, diesel, or other fuels to monitor the level and prevent tanks from becoming excessively empty.

Chemical storage: Mechanical level switches are used in the chemical industry to monitor the level of various liquid chemicals.

Wastewater management: For controlling the water level in wastewater tanks and sewage systems.

Industrial Applications: In various industrial processes where fluid levels must be closely monitored to ensure optimal operation.

The choice of a mechanical level switch depends on the specific requirements of the application, such as the type of fluid, environmental conditions and desired switching capacity.